Military rechargeable batteries are essential components powering advanced military technology across various applications. These batteries provide reliable energy storage solutions that are crucial for missions requiring durability and longevity in challenging environments.

Importance of Military Rechargeable Batteries

Military operations demand military power solutions that can withstand rigorous conditions and extended deployments. Rechargeable batteries are preferred for their ability to be reused, reducing logistical strain and environmental impact compared to single-use alternatives.

Applications in Military Technology

Military rechargeable batteries are integral to:

- Portable Electronics: Powering communication devices, GPS systems, and night vision goggles essential for situational awareness.

- Unmanned Systems: Providing energy for drones, unmanned aerial vehicles (UAVs), and autonomous ground vehicles used in reconnaissance and surveillance.

- Weapon Systems: Energizing advanced weapon platforms, such as missile guidance systems and laser targeting devices, ensuring precision and effectiveness.

Performance and Durability

The military power solutions industry prioritizes batteries that offer:

- High Energy Density: Packing more power into smaller, lightweight packages for increased mobility and reduced weight burden on soldiers.

- Shock and Vibration Resistance: Withstanding rough terrain and combat conditions without compromising performance.

- Long Cycle Life: Enduring multiple charge-discharge cycles reliably to support prolonged missions.

Challenges in Military Battery Technology

Developing military rechargeable batteries faces unique challenges:

- Temperature Extremes: Operating in environments from freezing cold to scorching heat requires batteries that maintain performance across wide temperature ranges.

- Security and Reliability: Ensuring batteries are resistant to tampering and capable of providing uninterrupted power in critical situations.

Innovations Driving Military Power Solutions

Advancements in battery technology are crucial for enhancing military power solutions:

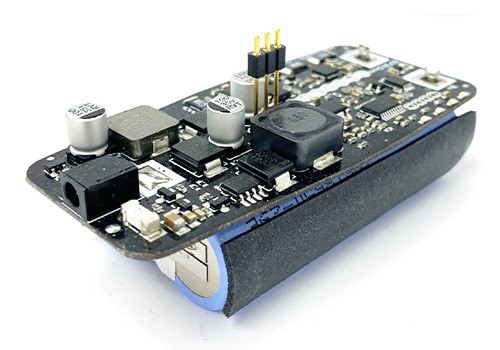

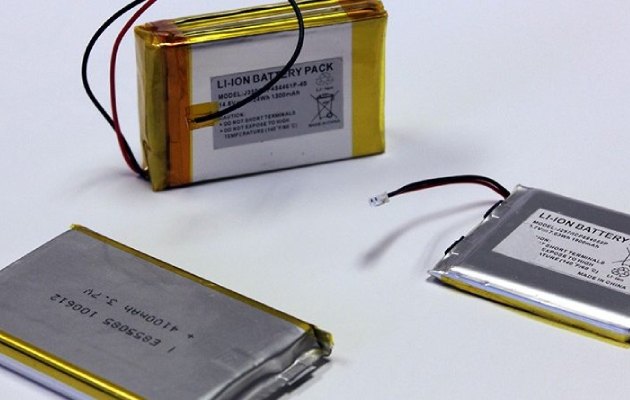

- Improved Chemistry: Lithium-ion and lithium-polymer batteries offer higher energy densities and longer operational life spans compared to traditional alternatives.

- Smart Battery Management: Integrated systems monitor and optimize battery usage, extending operational uptime and reliability.

- Alternative Power Sources: Exploring renewable energy integration and hybrid solutions to reduce reliance on conventional fuels and extend mission capabilities.

Future Outlook

The future of military technology hinges on sustainable and resilient military power solutions:

- Enhanced Integration: Seamless integration of batteries into wearable technology and soldier systems to enhance mobility and operational effectiveness.

- Environmental Impact: Emphasis on eco-friendly battery disposal and recycling practices to minimize environmental footprint and comply with regulatory standards.

Applications in Military Technology

Military rechargeable batteries are integral to:

- Portable Electronics: Powering communication devices, GPS systems, and night vision goggles essential for situational awareness.

- Unmanned Systems: Providing energy for drones, unmanned aerial vehicles (UAVs), and autonomous ground vehicles used in reconnaissance and surveillance.

- Weapon Systems: Energizing advanced weapon platforms, such as missile guidance systems and laser targeting devices, ensuring precision and effectiveness.

Sustainability and Efficiency

In addition to performance, military power solutions are increasingly focusing on sustainability and efficiency:

- Energy Conservation: Implementing energy-efficient technologies and practices to maximize battery life and reduce overall energy consumption during missions.

- Reduced Logistics Footprint: Utilizing rechargeable batteries minimizes the logistical strain of transporting and disposing of single-use batteries, contributing to operational efficiency and cost savings.

Conclusion

Military rechargeable batteries are indispensable for modern military power solutions, providing reliable energy storage essential for various applications in defense technology. As advancements continue, companies like Emerging Power are at the forefront of developing innovative battery technology to meet the stringent demands of military operations. Their contributions ensure that soldiers have access to the power they need, when they need it, enhancing mission success and safety in the field.