Lithium-ion batteries have become indispensable power sources in various applications, from consumer electronics to electric vehicles. With their high energy density and rechargeable nature, these batteries have revolutionized modern technology. However, their design and manufacturing require stringent quality control measures to ensure safety, performance, and reliability.

Understanding the Importance of Quality Control

As the demand for lithium-ion batteries continues to rise, lithium-ion battery suppliers and manufacturers face increasing pressure to deliver products that meet stringent standards. One of the key reasons for emphasizing quality control in battery design is safety. Lithium-ion batteries have the potential to cause fires or explosions if not designed and manufactured properly. Therefore, implementing robust quality control measures is crucial to minimize the risk of such incidents.

Key Quality Control Measures

- Material Selection: The quality of lithium-ion battery components, such as electrodes, electrolytes, and separators, directly impacts performance and safety. Suppliers must carefully evaluate and select materials from reputable sources to ensure consistency and reliability.

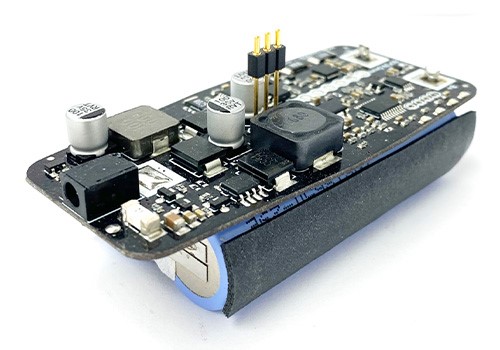

- Dimensional Accuracy: Proper lithium-ion battery dimensions are essential for compatibility and performance. Any deviations from specified dimensions can affect the fitment of the battery in devices or battery packs, leading to operational issues. Therefore, manufacturers employ precise machining and measurement techniques to maintain dimensional accuracy.

- Electrode Coating: The uniformity and thickness of electrode coatings significantly influence battery performance. Quality control measures involve monitoring coating thickness, adhesion, and uniformity to ensure optimal electrochemical performance and longevity.

- Cell Assembly: During cell assembly, various factors such as temperature, humidity, and contamination can affect battery quality. Strict protocols and cleanliness standards are enforced to minimize the risk of defects and ensure consistent assembly quality.

- Testing and Inspection: Comprehensive testing and inspection procedures are integral to quality control in lithium-ion battery manufacturing. This includes performance testing, safety testing, and rigorous quality checks at each stage of production to identify any deviations from specifications.

The Role of Suppliers

For businesses involved in sourcing lithium-ion batteries, partnering with reliable suppliers is paramount. Reputable lithium-ion battery suppliers prioritize quality control throughout the design and manufacturing process. They adhere to industry standards and regulations, invest in advanced technologies, and maintain robust quality management systems to deliver products that meet or exceed customer expectations.

Ensuring Long-Term Reliability

In addition to meeting immediate performance requirements, quality control measures in lithium-ion battery design also contribute to long-term reliability. By ensuring consistency, durability, and safety, manufacturers can enhance the lifespan of batteries and minimize the likelihood of premature failures or performance degradation.

Summing Up

Quality control is a fundamental aspect of lithium-ion battery design and manufacturing. By implementing stringent measures to select materials, maintain dimensional accuracy, optimize coating processes, ensure proper assembly, and conduct thorough testing, manufacturers can deliver products that meet the highest standards of safety, performance, and reliability. For businesses seeking reliable lithium ion battery suppliers, prioritizing quality is essential for long-term success. At Emerging Power, we uphold the highest standards of quality control to meet the diverse needs of our customers. For more details, approach our experts anytime.