Did you know that improper charging habits can reduce battery lifespan by up to 30%? Li polymer battery manufacturers are constantly working to improve battery efficiency, but user practices play a crucial role in maintaining battery health. Understanding the right way to charge these batteries can extend their lifespan and improve performance.

The Importance of Proper Charging for Li-Polymer Batteries

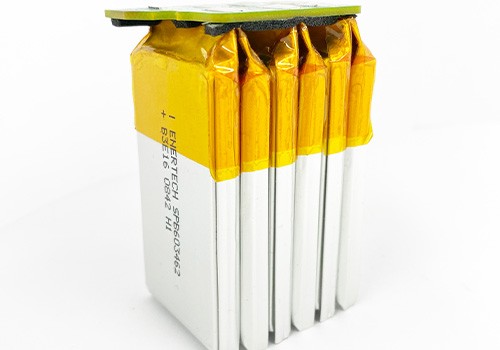

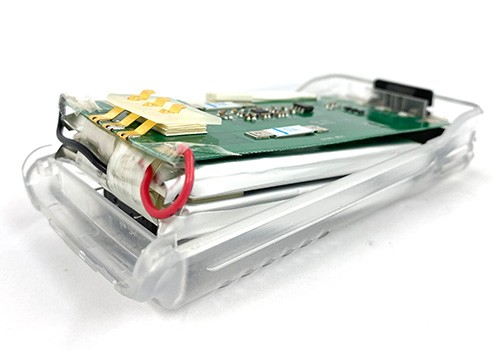

Li-polymer batteries are widely used in smartphones, laptops, drones, and other portable devices. Unlike older battery types, they offer higher energy density, lightweight designs, and better safety features. However, improper charging can degrade their performance over time.

Common Charging Mistakes That Reduce Battery Life

Many users unknowingly damage their batteries by following poor charging habits. Here are some mistakes to avoid:

- Overcharging: Keeping the battery plugged in after reaching 100% can generate excess heat, which degrades battery cells.

- Deep Discharges: Allowing the battery to drain completely before recharging can shorten its lifespan.

- Using Cheap Chargers: Low-quality chargers may deliver inconsistent power, damaging battery cells.

- Charging in Extreme Temperatures: High heat or extreme cold affects battery chemistry, reducing efficiency.

By avoiding these mistakes, users can significantly extend the lifespan of their Li-polymer batteries and maintain device performance.

Best Charging Practices for Longer Battery Life

To get the most out of your battery, follow these simple charging strategies:

- Keep the Battery Between 20% and 80%

Avoid letting the battery drop below 20% or charge beyond 80%. Staying within this range reduces stress on battery cells and extends lifespan.

- Use a Quality Charger

Always use a charger from a trusted lithium battery distributor. A high-quality charger provides stable voltage and protects against overheating.

- Avoid Fast Charging When Not Needed

Fast charging is convenient, but frequent use generates heat and degrades battery cells. Use it only when necessary.

- Unplug After Reaching Full Charge

Leaving the device plugged in overnight can cause unnecessary wear. If possible, unplug it once it reaches full charge.

- Store Batteries Properly

If storing a device for a long period, keep the battery level at around 50% and store it in a cool, dry place.

How Li-Polymer Battery Manufacturers Improve Battery Lifespan

Top Li-polymer battery manufacturers are developing advanced technologies to improve battery life and charging efficiency. Some of these innovations include:

- Smart Battery Management Systems (BMS): These systems regulate charging and discharging to prevent overcharging and overheating.

- Improved Electrolytes: Researchers are working on new materials that enhance battery stability and longevity.

- High-Efficiency Charging Algorithms: These optimize charging speed without causing excessive heat buildup.

The Role of a Trusted Lithium Battery Distributor

Reliable lithium battery distributors provide high-quality batteries that last longer and perform better. When purchasing batteries, it’s important to choose suppliers who follow strict quality control standards.

Emerging Power: A Leader in Battery Solutions

Emerging Power is a trusted name in the battery industry, offering high-performance Li-polymer batteries and advanced charging solutions. The company provides custom battery solutions for various industries, ensuring efficiency and reliability.

Conclusion

Extending battery lifespan requires both technological advancements and proper user habits. By following the right charging practices and choosing high-quality batteries from a trusted lithium battery distributor, users can enjoy longer-lasting, more efficient power solutions. With industry leaders like Emerging Power driving innovation, the future of battery technology looks promising.