In recent years, polymer batteries have gained significant attention for their potential to replace traditional lithium-ion batteries. As technology advances, polymer battery manufacturers are creating alternatives that promise better performance, safety, and efficiency. If you’re in the market for battery solutions, understanding the benefits of polymer batteries over lithium-ion batteries can help you make an informed choice.

What are Polymer Batteries?

Polymer batteries are a type of lithium-ion battery, but they use a solid or gel-like polymer electrolyte instead of the liquid electrolyte found in traditional lithium-ion batteries. This simple change makes polymer batteries lighter, safer, and more flexible, making them ideal for a variety of applications.

- Increased Safety

One of the biggest advantages of polymer batteries is their enhanced safety features. Traditional lithium-ion batteries can be prone to leaking or catching fire if they’re damaged or overcharged. This is due to their liquid electrolyte, which is flammable. Polymer battery manufacturers have solved this issue by using solid or gel-like electrolytes, which are much less likely to catch fire or leak, even under extreme conditions. This makes polymer batteries a safer choice for use in everything from mobile phones to electric vehicles.

- Lighter and More Flexible

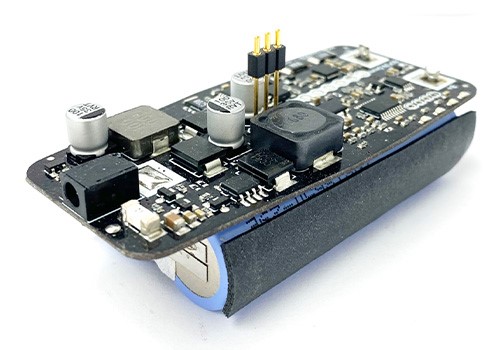

Polymer batteries are generally lighter than traditional lithium-ion batteries. This is especially useful for products that need to keep weight to a minimum, such as drones, electric vehicles, and portable electronics. Additionally, polymer batteries can be made in different shapes and sizes, offering more design flexibility. This means that custom battery pack manufacturers can create battery packs that fit perfectly into devices that require unusual shapes, such as wearable gadgets or slim laptops.

- Higher Energy Density

Polymer batteries can store more energy in a smaller space compared to lithium-ion batteries. This means they can provide longer battery life without the need for a large, bulky battery pack. With the increasing demand for compact, high-performance batteries, polymer batteries are a preferred option in industries where energy density is crucial, such as in electric vehicles (EVs) and aerospace.

- Better Thermal Stability

Polymer batteries handle heat much better than traditional lithium-ion batteries. This means they are less likely to overheat during charging or use, which is crucial for maintaining battery life and preventing safety issues. Custom battery pack manufacturers can design polymer battery packs that offer superior performance in high-temperature environments, making them ideal for a variety of applications, from industrial machinery to consumer electronics.

- Enhanced Durability

Polymer batteries generally have a longer lifespan compared to traditional lithium-ion batteries. This is because the solid or gel electrolyte is more stable and less likely to degrade over time. As a result, devices powered by polymer batteries tend to last longer and require fewer replacements. This makes them a cost-effective option for industries that rely on long-lasting battery performance, such as medical devices and renewable energy systems.

- More Environmentally Friendly

Polymer batteries are also seen as more eco-friendly. Since they don’t contain harmful liquids, they are easier to recycle and have a lower environmental impact compared to traditional lithium-ion batteries. With increasing concerns over the environmental impact of battery waste, many manufacturers are turning to polymer batteries as a more sustainable option.

- Faster Charging Times

Polymer batteries can be designed to charge faster than traditional lithium-ion batteries. This is because of their superior conductivity and more efficient energy transfer. For consumers, this means less time spent waiting for their devices to charge, while for businesses, faster charging can mean better productivity and less downtime for battery-operated equipment.

Why Choose Polymer Batteries?

Polymer batteries offer numerous advantages over traditional lithium-ion batteries. They are safer, lighter, more durable, and have better thermal stability. For companies that need customized power solutions, custom battery pack manufacturers can create polymer batteries that meet specific needs, providing both performance and safety.

Takeaways

Emerging Power specializes in creating high-quality polymer batteries tailored to your unique needs. Whether you’re designing a new electronic device, an electric vehicle, or a renewable energy system, we have the expertise to deliver the perfect battery solution. Let us help you power your next project with cutting-edge polymer battery technology.