When designing custom lithium-ion battery packs, engineers often face a key challenge: balancing capacity and power density. These two factors are crucial for determining how well a battery performs in various applications. Custom battery packs need to be tailored to specific needs, and understanding the trade-offs between capacity and power density is essential for optimizing performance.

What Is Capacity and Power Density?

Capacity refers to the amount of energy a battery can store. It is usually measured in milliampere-hours (mAh) or ampere-hours (Ah). A higher capacity means the battery can store more energy, which translates to longer usage time before needing a recharge.

Power density, on the other hand, indicates how quickly a battery can deliver energy. It is usually measured in watts per kilogram (W/kg). A higher power density means the battery can provide more power quickly, which is important for applications requiring high bursts of energy.

The Trade-Offs Between Capacity and Power Density

1.Capacity vs. Power Density

Increasing the capacity of a custom lithium-ion battery pack often means sacrificing some power density. This is because batteries with higher capacity typically have larger cells or more active material, which can reduce their ability to deliver energy quickly. For example, a battery designed to provide long-lasting power might not be able to supply high bursts of power needed for devices with sudden energy demands.

Conversely, a battery designed for high power density might have less capacity. It can deliver energy quickly but will deplete faster and require more frequent recharging. This trade-off is a critical consideration when designing custom battery packs for different applications.

2.Application-Specific Requirements

The balance between capacity and power density depends on the application. For example:

- Portable Electronics: Devices like smartphones and tablets need a balance of both capacity and power density. They require enough energy to last through the day but also need the ability to handle high power bursts for tasks like gaming or video streaming.

- Electric Vehicles (EVs): EVs need high capacity to ensure long driving ranges. However, they also require good power density for acceleration and performance. Custom battery packs for EVs often focus more on capacity but must still maintain sufficient power density.

- Medical Devices: Many medical devices require batteries with high capacity to operate over long periods without frequent replacements. However, some devices also need the ability to deliver power quickly in emergencies. Here, custom battery packs are designed to prioritize capacity while still providing adequate power density.

Design Considerations for Custom Lithium-Ion Battery Packs

1.Cell Chemistry and Design

Different cell chemistries and designs impact both capacity and power density. For instance, lithium iron phosphate (LiFePO4) cells offer lower power density but high capacity and safety. In contrast, lithium cobalt oxide (LCO) cells provide higher power density but generally have lower capacity.

When designing a custom battery pack, the choice of cell chemistry can significantly affect the trade-off between capacity and power density.

2. Thermal Management

Effective thermal management is essential for optimizing both capacity and power density. High power density can generate more heat, which can affect battery performance and safety. Custom battery packs need to include proper cooling mechanisms to manage heat and maintain performance.

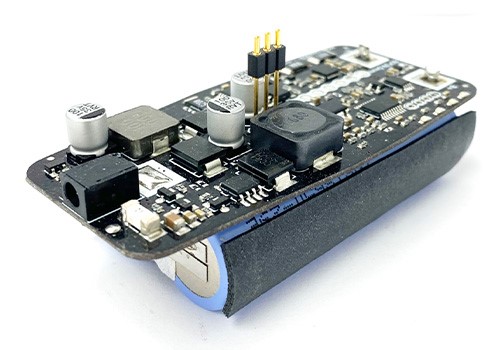

3.Battery Management System (BMS)

A well-designed Battery Management System (BMS) helps balance the capacity and power density of a custom battery pack. The BMS monitors and manages the battery’s charge and discharge rates, helping to optimize performance and extend battery life.

Summing Up

Balancing capacity and power density in custom lithium-ion battery packs is a complex process that requires careful consideration of the specific needs of the application. By understanding the trade-offs between these factors, designers can create custom battery packs that offer the right balance of energy storage and delivery. This optimization is crucial for ensuring that batteries perform effectively in their intended applications.

Emerging Power, a leading custom lithium battery manufacturer, designs custom lithium-ion battery packs that meet the unique needs of various industries. Whether you need high capacity, high power density, or a balance of both, our expertise ensures that your battery solutions are tailored to deliver optimal performance.