Did you know that the effectiveness of night vision goggles batteries greatly depends on their size and weight? These factors are crucial for military personnel, law enforcement, and outdoor enthusiasts. They impact how comfortable the goggles are to wear and how long they can be used without needing a recharge. In this blog, we will explore why battery size and weight matter so much in night vision technology.

Importance of Battery Size

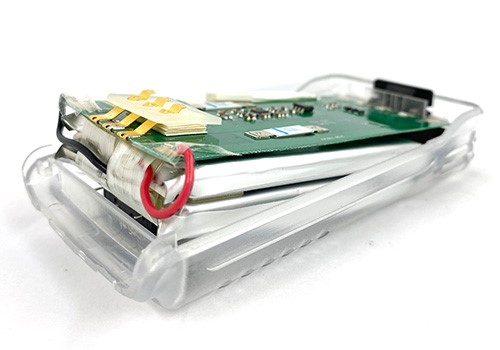

The commercial lithium-ion battery is popular in many devices, including night vision goggles. One key reason is its ability to store a large amount of energy in a small space. A smaller battery can provide enough power while making the goggles lighter. This is essential for users who need to wear them for extended periods. A heavy battery can lead to fatigue and discomfort.

Moreover, the design of night vision goggles often prioritizes compactness. With a smaller battery, manufacturers can create a sleeker design. This allows for better visibility and ease of use. A lightweight device is less likely to hinder movement. Therefore, having an appropriately sized battery plays a crucial role in enhancing user experience.

Weight Considerations

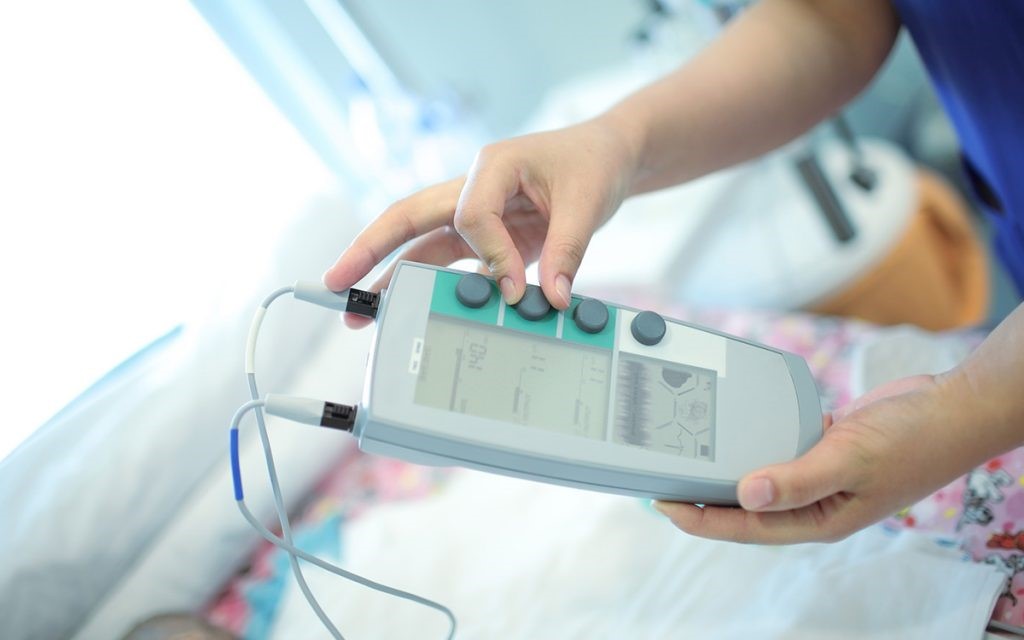

The weight of night vision goggles batteries significantly affects the overall usability of the device. If the goggles are too heavy, they can become burdensome. This is especially true for military personnel who may need to wear them for long hours. Heavier goggles can cause neck strain and discomfort, leading to decreased efficiency in the field.

A lighter battery can also improve the balance of the goggles. If the battery is heavy, it can throw off the balance, making it difficult to aim or observe properly. This can be critical during nighttime operations where stability and clarity are necessary for safety.

Energy Efficiency

While size and weight are essential, energy efficiency is equally important. A compact battery must still deliver enough power for the night vision goggles to function effectively. The commercial lithium-ion battery excels in this area. These batteries provide a high energy density, meaning they can store more energy in a smaller package.

Efficient energy use ensures that the goggles can operate for longer periods. Users can rely on their equipment without worrying about frequent recharges. This is particularly crucial in tactical situations where every second counts.

Advancements in Battery Technology

Recent advancements in battery technology are also worth mentioning. Manufacturers are continuously working on creating batteries that are lighter, smaller, and more efficient. Innovations in materials and design are leading to improvements in battery life. These advancements help meet the demands of users who require reliable performance in the field.

For example, some newer models of night vision goggles batteries are now using advanced lithium polymer technology. This technology allows for even smaller and lighter batteries while maintaining high energy output. Such developments enhance the usability of night vision goggles significantly.

In summary

The size and weight of night vision goggles batteries play a vital role in their performance and user experience. A well-designed battery can provide sufficient power without adding unnecessary weight. As battery technology continues to improve, users can expect lighter and more efficient options.

If you are looking for high-quality commercial lithium-ion battery solutions, consider Emerging Power. Our innovative products are designed to meet the needs of various applications, including night vision technology. We focus on creating batteries that are lightweight and powerful, ensuring that you get the most out of your devices. With Emerging Power, you can trust that your equipment will perform reliably when it matters most.